September 30, 2025

In the demanding world of construction, formwork quality can make or break project profitability. Poor shuttering choices cost contractors thousands in repairs, delays, and material replacements. Film Faced Plywood revolutionizes concrete work with its phenolic-coated surface that delivers smooth finishes and withstands 20-40 reuses compared to ordinary plywood’s 2-3 cycles. This explores how choosing the right film faced plywood boost construction efficiency, reduce long-term costs, and ensure professional-quality results across residential buildings, commercial complexes, and large infrastructure projects.

What is Film Faced Shuttering Plywood

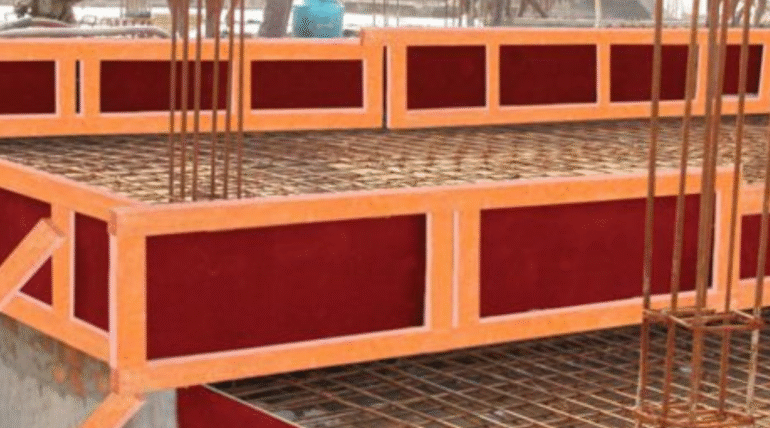

Film Faced Shuttering Plywood is construction-grade plywood enhanced with a durable phenolic film coating on both surfaces. This waterproof barrier transforms ordinary plywood into professional-grade formwork that resists moisture, prevents warping, and delivers smooth, high-quality concrete finishes.

During manufacturing, the phenolic film bonds permanently under high pressure and temperature, creating a non-porous surface that releases easily from cured concrete. Available in standard 4×8 feet sheets with thicknesses ranging from 12mm to 25mm, this engineered material combines the structural strength of plywood with the long-lasting durability of phenolic resin.

Why Choose Film Faced Shuttering Plywood

Film Faced Plywood is a contractor’s trusted material for modern construction because of its strength, smooth finish, and high reusability. Designed with a protective film coating, it resists moisture, chemicals, and wear, making it ideal for demanding projects.

- Foundation and Footing Work: It ensures precision and durability in foundations, footings, and basements where accuracy cannot be compromised.

- High-Rise Wall Shuttering: Perfect for repeated slab casting and wall shuttering, saving both time and cost across multiple floors.

- Infrastructure Projects: From bridges to tunnels and dams, it withstands heavy loads and harsh site conditions with ease.

- Architectural Concrete Elements: For exposed concrete walls, precast blocks, or decorative finishes, it delivers a flawless surface that enhances aesthetics.

Simply put, Film Faced Shuttering Plywood combines performance and economy, making it indispensable for quality-driven construction.

Uses of Film Faced Shuttering Plywood

Film Faced Shuttering Plywood is the go-to material for construction projects where concrete quality, durability, and multiple reuses are critical. Its versatility and resilience make it suitable for residential, commercial, and large-scale infrastructure projects, even in challenging conditions such as monsoon seasons.

Key applications include:

- Foundation and Footing Work: Ensures smooth finishes and precise dimensions in basements, walls, and footings, delivering long-lasting strength and reliability.

- High-Rise Wall Shuttering: Ideal for slab casting and wall formwork in multi-storey buildings, reducing costs and improving efficiency through repeated reuse.

- Infrastructure Projects: From bridges, tunnels, and dams to culverts, it performs under heavy loads and harsh site conditions, making it a trusted choice for civil engineering works.

- Architectural Concrete Elements: Produces flawless surfaces for decorative walls, exposed concrete features, and precast elements, minimizing post-finishing work.

Where Film Faced Shuttering Plywood Fits Best

Knowing when and where to use Film Faced Shuttering Plywood ensures maximum performance, durability, and cost-efficiency. Its moisture resistance, smooth surface, and long-lasting strength make it indispensable for a variety of construction scenarios, from residential foundations to large infrastructure projects.

- Large-Scale Construction Projects: Ideal for multi-storey buildings, commercial complexes, and infrastructure works where repeated reuse delivers cost savings and efficiency.

- Monsoon Season Construction: Withstands heavy rainfall without swelling or losing strength, keeping projects on schedule even in wet conditions.

- Quality-Conscious Applications: Perfect for architectural or structural projects requiring smooth concrete finishes, reducing post-finishing labor and material costs.

- High-Pressure Concrete Pours: Provides dimensional stability for tall walls, deep foundations, and heavy slabs where strength cannot be compromised.

Types of Film Faced Shuttering Plywood Available

Before selecting Film Faced Shuttering Plywood, it’s important to understand the different varieties and their ideal applications. Each type is engineered for specific construction needs.

- Brown Film Faced Plywood: A reliable, cost-effective choice for most projects, offering good water resistance and smooth concrete finishes.

- Black Film Faced Plywood: A premium grade with higher density and durability, designed for longer reuse cycles and harsh conditions.

- Anti-Slip Film Faced Plywood: Built with textured surfaces, it’s perfect for ramps, walkways, and worker safety zones where grip is essential.

- Hardwood vs Softwood Core: Hardwood cores provide superior strength for heavy-duty shuttering, while softwood cores keep costs lower for lighter applications.

Find our moisture resistant shuttering plywood suited for construction sites where durability and concrete quality are primary concerns.

Film Faced Shuttering Plywood vs Ordinary Plywood

The real difference between Film Faced Shuttering Plywood and ordinary plywood becomes clear when you compare them on key performance factors.

| Feature | Film Faced Shuttering Plywood | Ordinary Plywood |

| Water Resistance | Excellent phenolic coating | Absorbs moisture |

| Reuses | 20–40 times | 2–3 times maximum |

| Concrete Finish | Smooth, professional quality | Rough, needs extra work |

| Initial Cost | Higher investment | Lower upfront cost |

| Long-Term Value | Superior ROI, fewer replacements | Frequent replacement needed |

| Weather Resistance | Withstands monsoons easily | Fails in wet conditions |

Selection Guide & Best Practices

Think of Film Faced Shuttering Plywood as the backbone of your concrete work. A poor choice can cost you in repairs, delays, and wasted materials, while the right choice delivers smoother finishes and more reuses. So, how do you ensure you’re getting value?

Start with quality.

Always inspect the film coating and edge sealing—these small details decide whether your plywood lasts five pours or fifteen. Confirm the thickness, grade, and supplier certifications before signing the deal. Remember, a trusted supplier often saves you more in the long run than a “cheap” option.

Next, think longevity.

Proper handling and care matter just as much as selection. Store panels flat in a dry space, coat them with a release agent before use, and clean them after every pour. These simple steps protect your investment and stretch every sheet further.

When you follow these plywood quality standards

Conclusion

Film Faced Shuttering Plywood is more than just a material — it’s an investment in quality construction. Its strength, moisture resistance, and reusability deliver real savings over time, making it a reliable partner for demanding projects like foundations, high-rise structures, and architectural concrete work. With proper handling, this plywood ensures smooth finishes and long-lasting performance, reducing both effort and costs on site.

If you’re looking for high-quality Film Faced Shuttering Plywood that balances durability with value, explore Premium Ply’s different range of plywood. As one of India’s trusted plywood manufacturers, we’re committed to helping contractors, developers, and builders achieve stronger, smarter, and more profitable outcomes.

Q. What is Film Faced Shuttering Plywood?

A. Film Faced Shuttering Plywood is construction-grade plywood with a phenolic film coating designed to create smooth concrete surfaces and withstand multiple reuses in formwork applications.

Q. How many times can Film Faced Shuttering Plywood be reused?

A. Quality Film Faced Shuttering Plywood can be reused 20-40 times with proper care, significantly more than ordinary plywood’s 2-3 uses.

Q. Where can Film Faced Shuttering plywood be used?

A. It’s ideal for foundation work, wall shuttering, high-rise construction, infrastructure projects, and anywhere smooth concrete finishes are required.

Q. What is the difference between brown and black Film Face Plywood?

A. Brown Film is standard quality for most applications, while black film offers superior durability and longer lifespan for demanding projects.

Q. How should Film Faced Shuttering Plywood be maintained?

A. Clean concrete residue after each use, apply release agents before pouring, store flat and dry, and protect edges from damage to maximize lifespan.